ABOUT GELCOAT RESTORATION & PRESERVATION

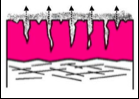

Dark colored gelcoat absorbs much more UV and heat from the sun than lighter colored gelcoat. Consequently, it breaks down rapidly into short-chain, low molecular weight “chalk” (as seen in picture to the left). This can happen in such a way that “pores” or micro crevices are eaten down into gel-coat. This situation is analogous to the way in which rust forms on metal. It starts on the surface and then eats down into the metal. Abrasives only remove the surface chalking and cannot reach down into the deep pores filled with chalk. In fact, abrasives can remove good gelcoat and scratch up the surface greatly increasing surface area exposed to new oxidation.

Our classic Cleanser/Conditioners (SEA GLOW™ & NEUTRAL CLEAR™) and our new (more potent) ELIXIR™ chemically dissolve away “chalky” oxidation , even deep down in the pores. That is why our products uniquely remove the “grayish cast” of dark-colored gelcoat (e.g black, dark blue) due to lighter colored chalky oxidation products located deep down in these pores. Stains, which tend to accumulate in highly absorbent chalk are also removed.

As well as being self-sealing due to its resin/wax content, ELIXIR™ is so rich in anti-oxidants and UV protectants that it is superior to ANY product in protecting dark/colored gelcoat against color fade & chalking (up to one year in the tropics). An outer coating of MIRROR HARD Superglaze™ gives astounding gloss with at least 3 years of water-beading protection,

Light-colored gelcoat absorbs less heat and UV and so the breakdown process is slower. In this case, partially broken down gelcoat forms an outer “spongy” surface that absorbs salts and pollutants. Our Cleanse/Conditioners and ELIXIR™ do not completely dissolve the broken down surface, as they do with chalk, but partially dissolve it. This makes the outer spongy layer very soft and crumbly so that it is easily removed by mild scuffing with the grey 3M pad included with our kits.

If this outer spongy layer is not removed, then our products will not appear to work as advertised and our resin coatings ( e. g. MIRROR HARD Superglaze™, SIMPLY BRILLIANT Superwax™ ) will soak into this spongy surface, leaving an initially disappointing mottled or dull surface, which can only be fixed by multiple applications. Note: this is one occasion when a single compounding step might be an advantage

On older non-skid textured gelcoat, a brass-bristled brush (available in any hardware store) is more suitable for removal of this outer. spongy layer. Then seal with our NON-SLIP Superglaze™ .

On smooth gelcoat the result should be virtually “as new” protection and gloss.

By contrast to ISLAND GIRL®'s resin coatings, Poliglow®, Vertglas™ and other water-based “wipe on” acrylics NEED gelcoat porosity as a “key” so that their coatings do not peel off. That is why such wipe-on products require 6 to 12 coats to produce a shine as opposed to our resin coatings, that only require 1 to 2 applications. Our resin coatings do not require special applicators to avoid “lap marks” and can be used on shiny newer surfaces to which they molecularly bond.

However both approaches are longer lasting than use of compounding and waxing that do “wear away” the gelcoat layer as discussed HERE.

THE HAWAIIAN 2-STEP PROCESS (see below):

NEW WHITE GELCOAT

OXIDATION BEGINS

CONTINUING TO ‘SPONGY’ POROSITY

GLOSSY RESTORED GELCOAT

ELIXIR™

removes oxidation, preserves & seals. MIRROR HARD™ adds extra gloss &

protection.

STAINED CHALKY OXIDATION REMOVED BY SEA GLOW™, NEUTRAL CLEAR (3 STEP PROCESS) OR ELIXIR™ (2-STEP PROCESS), as decribed HERE